1) Introducing well-known foreign technologies;

1) Introducing well-known foreign technologies;

2) Energy conservation and environmental protection; Electrode spacing ≤ 0.8mm;

3) The system operates completely enclosed, with no secondary leakage or pollution; The entire process from electrolysis to dosing is designed to be fully enclosed, without worrying about sodium hypochlorite and hydrogen leakage, ensuring safety and reliability;

4) The special electrode arrangement ensures that hydrogen produced by the electrode quickly escapes from the electrode surface, reduces electrolyte resistance, reduces energy consumption, and improves electrolysis efficiency;

5) Prepare sodium hypochlorite on site and add it immediately to solve the problem of sodium hypochlorite not being stored;

6) Fully automatic operation, only regular salt addition is required in daily life;

7) Compliance assurance, full computer program, PLC, residual chlorine online monitoring, good dosing ratio, ensuring compliance without wasting any excess chemicals;

8) Central control, can replace remote control, easy to operate;

9) Easy to master operations, staff can start working after simple training;

10) Jinchuan has many years of experience in sterilization and is very proficient in various sterilization technologies, with a deep understanding. It is a technical expert company. The company has achieved performance in over 2000 companies, including municipal sewage, tap water, hospital sewage, and oilfield water.

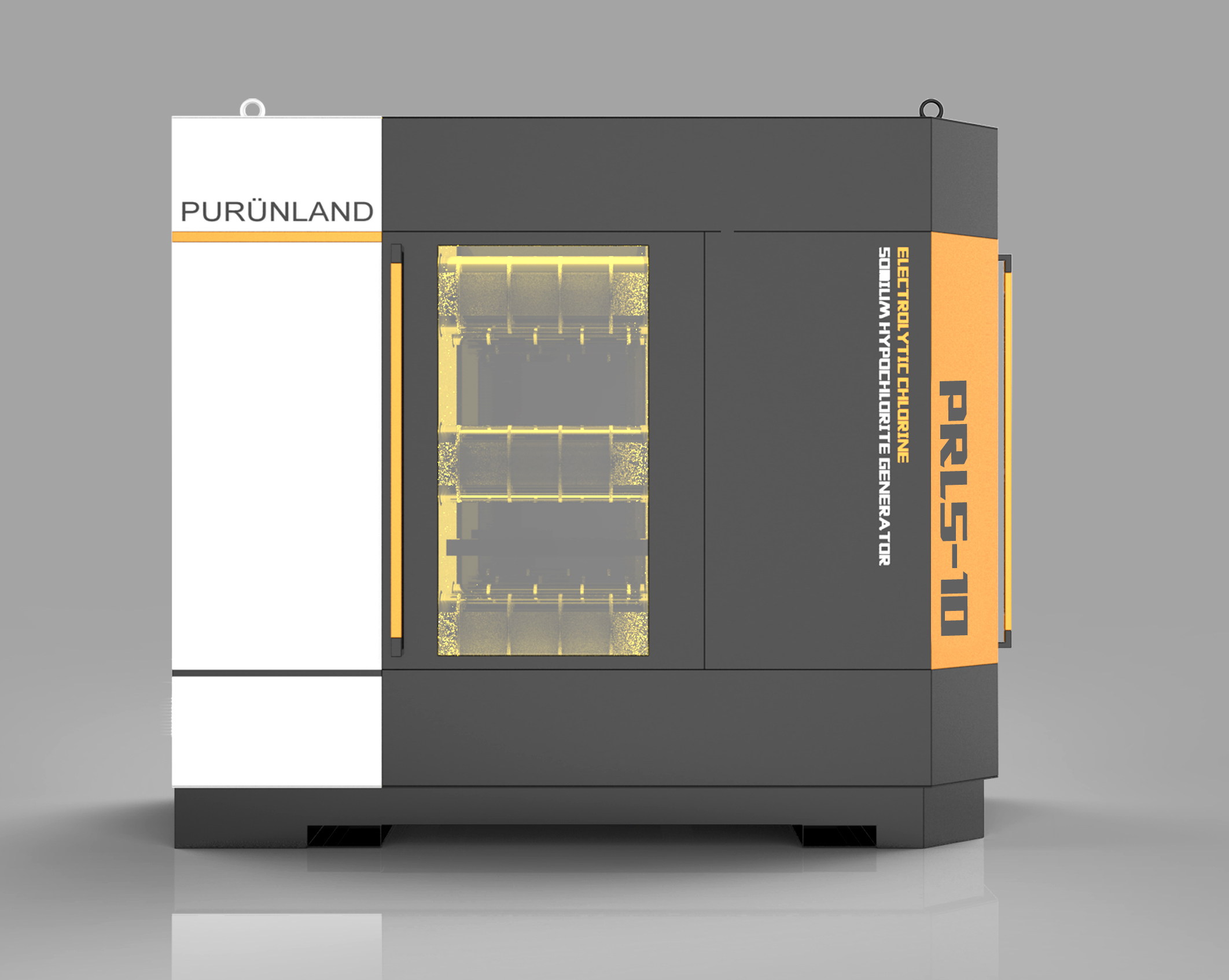

2 High quality core components and materials

1) Design parameters of sodium hypochlorite generator electrode:

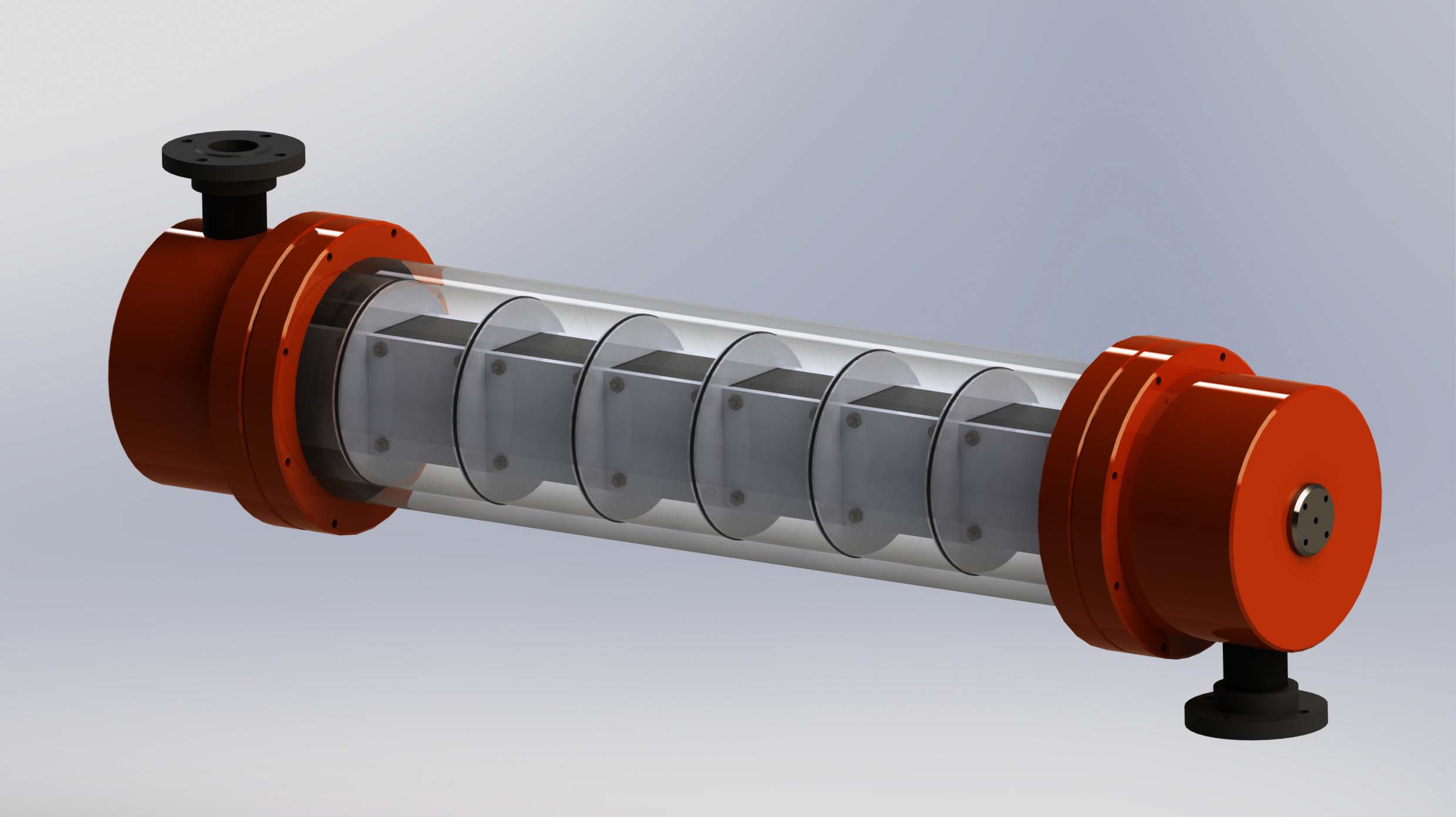

Structure of generator: Heterogeneous compound electrode

Effective chlorine concentration: ≥ 0.8%

Anode lifespan: ≥ 5 years

Cathode lifespan: ≥ 20 years

AC power consumption: ≤ 4.5kW. h/kg

DC power consumption: ≤ 3.6KWh/kg · Cl2

Anode material: Titanium based multicomponent coating (DSA anode)

Cathode material: TA2

Pickling cycle: ≥ 720 hours

Electrolytic cell: transparent organic glass (intuitive)